APPLICATIONS

Steam Trap Testing

Reduce Energy Costs and Increase Process Stability with Ultrasonic Testing Devices

The regular inspection of valves and steam traps is essential for preventive maintenance. The early detection of steam trap leaks or fails and signs of wear leads to increased operational reliability, and considerable cost savings.

Advantages at a Glance

- Reduce energy costs by up to 20 %

- Increase process stability

- Check all types and brands quickly and inexpensively

- SteamExpert App for steam trap testing for SONAPHONE

- SteamExpert Software module for SONAPHONE DataSuite

- Reporting and Trending

Products

- SONAPHONE

- SONAPHONE POCKET

Experts assume that around 15 to 20 percent of steam generated is lost through leaking steam traps. With only one leaky steam trap (thermodynamic bimetal, DN25, system pressure 11 barg) approx. 22 kg of steam per hour and thus approx. 190 t per year are lost (with 8,400 operating hours per year). With production costs of € 35 / t, this loss adds up to around € 6,600 per year.

COST

Reduce costs through process optimization of steam trap testing tasks

PROCESS STABILITY

Save time by optimizing of the testing process Ensure process stability

SECURITY

Operational safety Avoidance of accidents

KNOWLEDGE

Qualification of the personnel deployed Reduce susceptibility to errors

PRODUCT QUALITY

Quality assurance through reducing the susceptibility to errors

ENVIRONMENT

Reduce CO2 emission

Complexity

- Operator needs in-depth knowledge of steam trap testing for efficient testing

- Large number of different types of traps with different pressures and temperatures, thus increased time expenditure as well as increased susceptibility to errors

- Time-consuming data collection and documentation of measurement data, images and texts

The ultrasonic testing device SONAPHONE is used for steam trap and valve inspections in many branches of industry.The SONAPHONE devices can be used for the testing of the functionality of any type of steam trap e.g. for float, thermodynamic and thermostatic traps or for valves in systems with a flow of steam. The device enables the control of the proper functionality of steam traps and also allows an estimation of any losses of steam within the system.The functionality of steam traps and valves is tested by analysing the typical ultrasound and temperature of the respective installation.

Our complete solutions for steam trap testing includes:

- SONAPHONE digital ultrasonic testing device

- BS20 broadband structure-borne sound and temperature sensor

- SteamExpert app for SONAPHONE

- SteamExpert module for PC Software SONAPHONE DataSuite

SONAPHONE

Digital Ultrasonic Testing Device for Maintenance 4.0

STEAMEXPERT APP

App on SONAPHONE for Steam Trap Testing

STEAMEXPERT SOFTWARE

Special module for SONAPHONE DataSuite PC Software

BS20

Broadband Structure-Borne Sound and Temperature Sensor

Signal processing in the SONAPHONE outputs different sound levels, which are significant depending on the application.

As a basis, raw level values are obtained from the filtered raw data with a sample rate of 1 ms. The derived level values are calculated and stored in much larger time intervals. The sample rate can be varied in the menu “Measurement settings” between 4 ms and 128 ms. It should be noted that the set sample rate has an influence on the representation of data in the spectrogram.

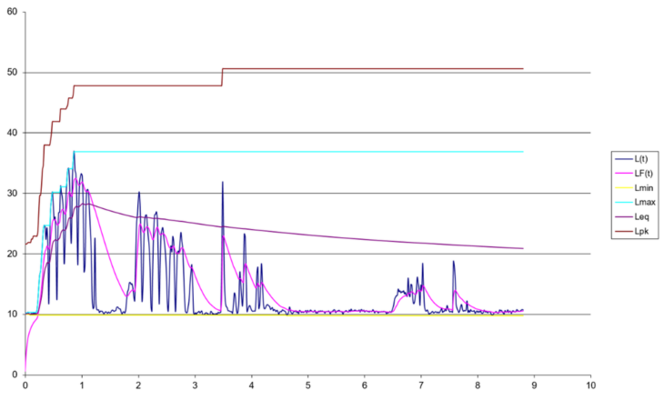

Level values are:

- L(t) – Instantaneous Level

The instantaneous level is derived directly from the raw level values and averaged according to the sample rate setting (between 4 ms and 128 ms). For better readability on the display of the SONAPHONE, the largest value out of 8 consecutive values is represented.

- LF(t) – Instantaneous Level with Time Weighting

The standardized Instantaneous Level with Time Weighting (also Fast Level) is exponentially averaged with a time constant of 125 ms. The Fast Level follows the physical measurement effect relatively slowly. In history, it has been used on pointer instruments and fast changing measurements to increase the readability of the values.

- Lmin – / Lmax – Minimum / Maximum Value of Instantaneous Level

This level is the minimum or maximum value of the Instantaneous Level L(t) (sample rate between 4 ms and 128 ms).

- Lpk – Peak Level

The Peak Level is based on the highest measured value in the raw data (sample frequency 256 kHz / sampling time 4µs). It should not be mistaken for the more averaged Maximum Value of Instantaneous Level (Lmax) – the Peak Level can be a few decibels above Lmax.

- Leq – Equivalent Continuous Sound Level

The Equivalent Continuous Sound Level is a standardized averaging level and is used to describe time-varying level values. It averages the sound energy over the measurement period according to specific rules.

It should be noted that due to averaging important information regarding frequency distribution or changing values over time are lost. Therefore, the Equivalent Continuous Sound Level is particularly meaningful when acoustic situations with similar characteristics are compared.

The level values Lmin, Lmax, Lpk, Leq are calculated from the data from the beginning of each measurement and shown on the display. Pressing the “Reset” button in the Levelmeter App will start a new measurement with newly calculated level values. During data recording, the values apply to the recording period.

Through signal processing, ultrasound can be converted into a secondary “downmixed” signal in the audible range.

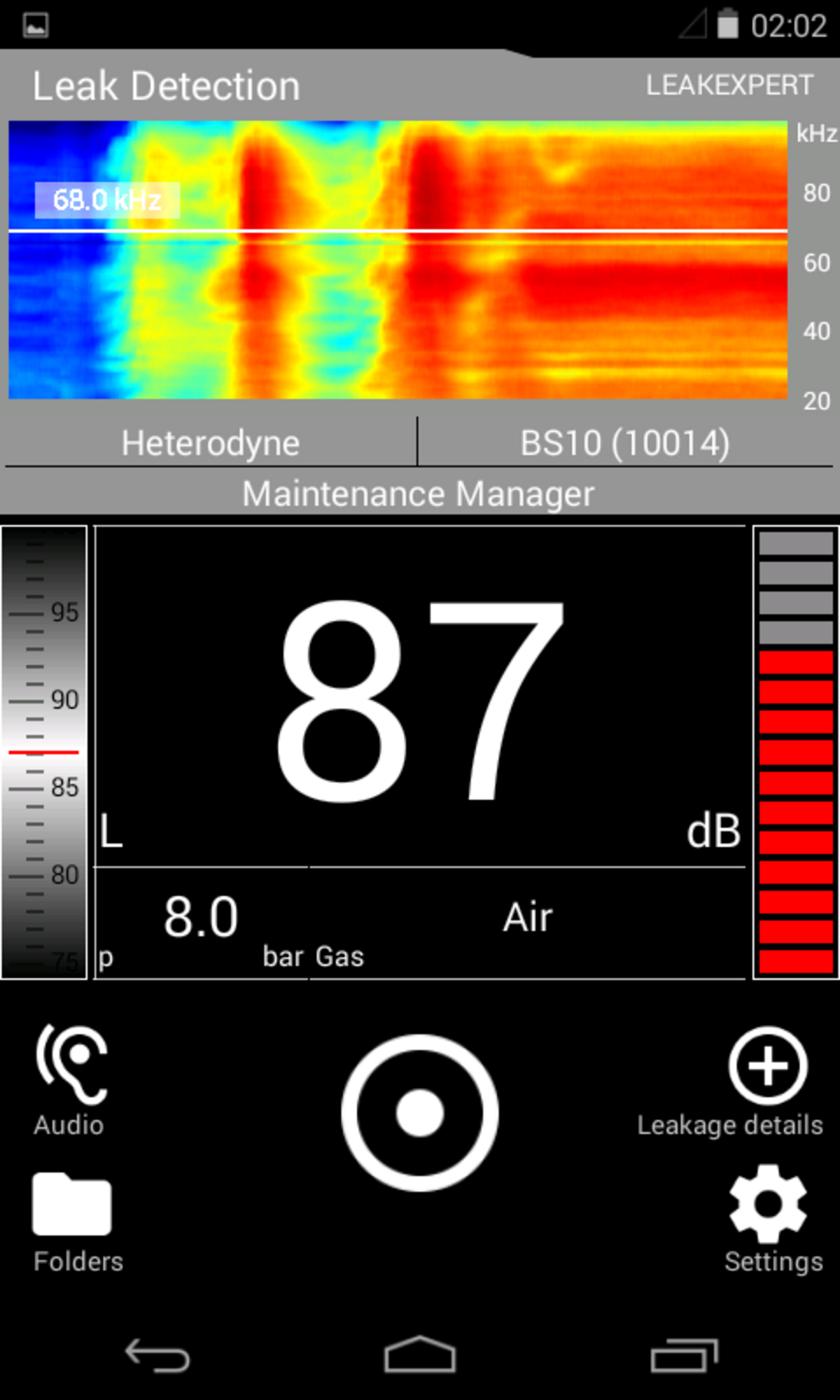

In the heterodyne method, a narrow frequency in the ultrasonic range is selected (e.g. carrier frequency of 40 kHz +/- 2 kHz) and transformed into the audible range via difference frequencies. The method is used in the traditional analogue test equipment, which work in the narrow band around 40 kHz. The broadband digital SONPAHONE® integrates this approach. By means of a shift of the carrier frequency (movable line in the spectrogram in the broadband 20 … 100 kHz), the corresponding narrow-band audio signal is made available.

In many cases a qualitative evaluation is already possible with the heterodyne method via the audible impression, for example in leak detection and in the basic evaluation of bearing condition.

In most cases, the ultrasound signals are distributed over a broad frequency range. This means that the information in the acoustic signal cannot be completely detected in a narrow frequency range. In the case of the SONAPHONE, which operates in broadband, it is possible to convert the signals using the phase vocoder method. Doing this, the entire frequency range of 20 … 100 kHz is compressed by a factor of 32. Despite little loss of information, the original acoustic situation in the broadband can be reproduced, the audible impression is available for the entire ultrasound range.

Both methods “sound” differently. The user can listen to the signal via built-in speakers or headphones. The sampling rates of the audio signals are 8 kHz. The volume of the signal changes in the same way as the intensity of the original high-frequency signals. In addition, the variation of the original signal over time is preserved so that the dynamics of events in the audible signal are reflected.

In addition, the SONAPHONE records the audible signals. They are available in WAV format and are thus also available for further data processing.